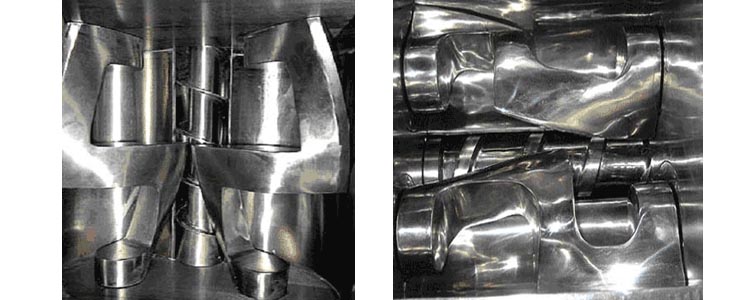

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solutions, adhesives, polymers etc. The mixing action is a combination of smearing, stretching, folding, dividing and recombining as the material is processed between the sigma blades and the container walls. Jacket arrangement is provided for heating or cooling application. In bigger models the container is tilted by a hydraulic cylinder to ensure complete discharge of mass.

SIGMA MIXER EXTRUDER - CAPACITY TABLE

Model No. |

Working Capacity (Liter) |

SHELL SIZE |

Total Capacity (Liter) |

MAIN GEAR BOX |

Mixer (HP) |

Extruder (HP) |

ABFSME – 50 |

30 - 50 |

16” X 16” |

75 |

4” |

1.0 – 1.5 |

5 – 7.5 |

ABFSME – 75 |

50 – 75 |

20” X 20” |

110 |

6” |

15 – 20 |

5 – 7.5 |

ABFSME – 150 |

75 – 150 |

24” X 24” |

200 |

8” |

30 – 40 |

10 – 15 |

ABFSME – 300 |

150 – 300 |

36” X 36” |

400 |

10” |

40 – 50 |

10 - 15 |

**Note – The actual power consumption shall depend upon the application and the properties of the material to be mixed (Density, Viscosity etc.)

** Note – As improvements in design are being made continuously, the above specifications should be considered for reference only. The equipment built may differ due to our policy of continues product development.

Note : Working capacity to be calculated @ 60% of Total Capacity.

Description

Sigma Mixer Extruder

The Kneader Extruder combines the efficiency of a double arm - sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials. Such as Adhesives, Explosives, Mastics, Sealing compounds, Biscuit dough's, Fiberglass resin dough's, Metal powders, Silicone rubber, Butyl rubber, Food and confectionery products, Moulding preparations, Soaps and detergents, Carbon pastes, Gaskets and Gland Packing's, Pencil erasers, Solid propellants, Ceramics Grinding wheel preparations, Pharmaceuticals, Sugar pastes, Chemicals, Hot-Melts, Plastics, Viscous rubber solutions, Chewing gum, Inks and pigment products, Putties, Crayon and pencil lead, Marzipan, Refractories.

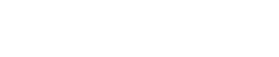

The Kneader Extruder includes a set of counter-rotating kneading blades and a discharge screw. The blades are mounted on a horizontal axis in a u-shaped trough. Below the blades in a separate cavity is the discharge screw. During the mixing cycle the blades rotate toward each other while the mixing screw rotates in a reverse direction, constantly feeding new materials into the mixing blades. After the mixing/kneading cycle is complete, the screw is reversed and it transports the mixed materials from the mix zone out through a discharge die and on to further processing or packaging.

- Low mixing time approx. 15% less time.

- Eliminates the manual task of scraping out sticky/tacky materials.

- Eliminates operator exposure to materials of elevated temperatures or of a toxic nature, thereby improving plant safety.

Many Different sizes and designs are available to meet the most stringent process needs. Kneader Extruders are manufactured in many sizes from 5 through 2500 Liters capacity. Other sizes manufactured on request.